Ensuring The Validity Of Results 17025

The ISO 17025 Procedure Bundle provides a starting point for new procedures or serves as a basis for enhancing existing procedures. Bundle includes 24 prewritten procedures in Microsoft Word and help to simplify the implementation of ISO 17025! QP-001: Estimating Measurement Uncertainty. As an ISO/IEC accredited lab, ensuring the validity of results should be a top priority. One of the goals of validity is to be able to identify trends using statistical techniques. To meet the requirements, the laboratory must develop a procedure for monitoring the validity of their results. The reporting requirements in ISO/IEC have some changes that laboratories will need to take into consideration. In addition to a few new requirements, there are changes in wording in some of the requirements. Clause 7.8.1.1 is new and requires that results are reviewed and authorized prior to release.

- Ensuring The Validity Of Results 17025 2017

- Ensuring The Validity Of Results 17025 Pa

- Ensuring The Validity Of Results 17025 Program

I am working to build an integrated QMS for a calibration lab and an inspection body which are established under the same company.The proposed accreditation scope of the calibration lab is as below:1. Pressure (up to 75 bar)4. Non-automatic weighing scales (up to 150 kg)The inspection body's scope is inspection of clean rooms and zones according to ISO 14664-1, -2 and -3.Anyway, I have constructed a QMS documentation as belows:1. Procedure 1 - Control of documents and Records3. Procedure 2 - Sales4.

Procedure 3 - Purchase5. Procedure 4 - Customer Relations6. Procedure 5 - Corrective and Preventive Action7. Procedure 6 - Control of Nonconforming Operation8. Procedure 7 - Management Review9. Procedure 8 - Internal Audit10.

Procedure 9 - Training11. Procedure 10 - Quality Assurance12. Procedure 11 - Clean Room Inspections and Tests13. Procedure 12 - Calibration14. Procedure 13 - Control of Data15.

Procedure 14 - Control of Reference EquipmentThe system structure is based on ISO 9001 plus 17020's and 17025's additional requirements.So. My questions to 17020 and 17025 experts are as follows (begining from the most important):ISO IEC 17025 clause 5.9 Assuring the quality of test and calibration results requires a procedure. The requirement states (in short);5.9.1 There must be a quality control procedure where data are recorded, and, statistical methods are applied for the review of the results. That monitoring must be planned and reviewed. Monitoring can contain,a. Building of internal quality control system by using certified reference materials,b.

Joining inter-lab test programmes, conducting proficiency tests etc.c. Re-conducting of tests or calibrations with the same or different methods,d. Re-conducting of tests or calibrations on the preserved material,e. Research on the different specs of the material.5.9.2 Quality control records/data must be analysed and planned operations are applied to correct the problem or to prevent reporting of nonconforming results when data are out of limits.Okay, I clearly understand 5.9.1. I will write down the method for proficiency tests (where two of our employess will conduct the same calibration) and joining inter-lab test programmes (where our AB, TURKAK, or any other accredited laboratory plans a test programme we will join, too), however, the problem is about 5.9.2.I understand there must be analysis if PT/ILC demonstrates a nonconformity. But, I have also seen some statistical methods (t-distribution, f test, z score, q test, chi square test, x cards) in a sample procedure.So, shall I apply statistical methods on client's calibration results?I mean,1. My hero acdemia saison 2 streaming vf.

Shall I apply statistical methods on each calibration step of an individual calibration of any client? For example, if we calibrate a T/C and use 10 calibration points, so I have 10 deviation values and an uncertainty value, shall I apply t-distribution on 10 deviation values?2. And, shall I compare the uncertainty value to similiar T/C calibrations which we have conducted before?Thanks in advance for answers.P.S. I have checked the thread That doesnot help me, I think. Yes, you are right, but, right for the expanded uncertainty As you probably know, every calibration method has its own method of uncertainty calculation, and, those are determined by internationally recognized reference documents if you are using standard referenced methods. After calculating the uncertainty you expand it by multiplying the uncertainty result with two.

But, that's something different than what I was asking.I asked, if I must apply any statistical method to check whether the distribution of the sample space (calibration step results) is meaningful or not, each time I calibrate something. I got an answer from another lab, that there is no need to apply those statistical methods for the calibration.Thanks for your kind interest.

The reporting requirements in ISO/IEC have some changes that laboratories will need to take into consideration. In addition to a few new requirements, there are changes in wording in some of the requirements.Clause 7.8.1.1 is new and requires that results are reviewed and authorized prior to release.The date of sampling needs to be included in the report if it is critical to the validity and application of the results. In the 2005 version the date of sampling was required if the test reports included the results of sampling.Reports need to have the date of issue, and need to list any additions to, deviations, or exclusions from the method.

Ensuring The Validity Of Results 17025 2017

(7.8.2.1)The standard now states that laboratories are responsible for all the information provided in the report, except when the information is provided by the customer. Information from the customer needs to be clearly identified and a disclaimer is required when the information from the customer can affect the validity of results. If samples are provided by the customer (i.e. The laboratory is not responsible for sampling), the report must state that the results apply to the sample as received. (Clause 7.8.2.2)When laboratories are responsible for sampling, there are specific reporting requirements. A new requirement is that sampling reports include the information required to evaluate measurement uncertainty for subsequent testing or calibration (Clause.8.5 (f))The standard now has requirements for reports that include statements of conformity. Decision rules need to be documented and need to take risk into account.

Ensuring The Validity Of Results 17025 Pa

The results with a statement of conformity need to be clearly identified as such, including which specifications are met or not met, and what decision rule has been applied. (Clause 7.8.6.1 and 7.8.6.2)When issued reports are changed, amended, or reissued, and change of information needs to be clearly identified. Where applicable, the reason for the change needs to be included in the report. (Clause 7.8.8.1)Remember, in addition to the changes covered here, there are wording changes.

Ensuring The Validity Of Results 17025 Program

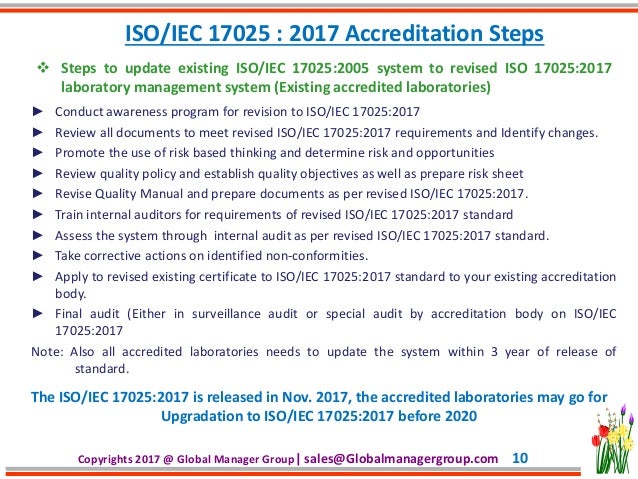

Laboratories need to familiarize themselves with the new requirements. The majority of the requirements related to reporting are similar to the previous requirements, however, changes to the wording may drive a change in your management system. Get to know the new requirements and conduct a so you can update your management system to meet the 2017 requirements.Share this post.